Machine type levanodi framar

0

FOUR SEPARATE MACHINE TYPE LEVANODI FRAMAR:

, MANUFACTURING 2005

, PORT-MANDRINE 70MM ARMOR CURRENT

, 4 MANDRINE PORT FREZE

, ADJUSTMENT OF ADJUSTMENT OF MILLING

, VERTICAL LOADING 140MM

, POWER OF THE MOTOR 0,6 / 0,8 HP

, ROTATION SPEED OF MANDRINS 700-1400MM

, GREUTATE 200 KG

Publication: 21-Mar-2018

Expiration: 21-Mar-2018

Quantity

1 bucati

Country & Region

Romania, Bucuresti

Delivery

EXW

Sell

Date: 2018-03-21

Contact manufacturer / supplier

BRICOPROD WOOD SRL

Address : BUCURESTI, BUCURESTI, RomaniaPhone: 004 0754911229

Fax: -----

Contact: MIHAI DOROBANTU (Dir General)

Company profile

Manufacturer |

Commercial correspondence can be in the following languages:Company Products

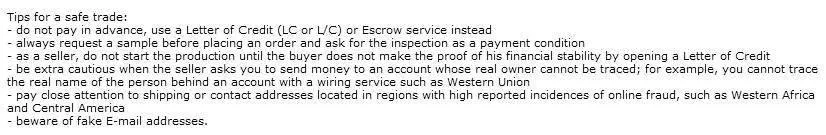

Tips for safe trading