We are import-export agency and we are offering pallets elements:

- Pine / Spruce Pallet Elements

We offers timber and semifinished goods used for production of different types of wooden pallets.

The blanks of EURO pallets, CP pallets and non-standard pallets are made from conifer (fir and pine). The boards are fresh-cut and natural humidity.

Below are standard production dimensions of 1st and 2nd quality (dimensions in millimeters):

EURO:

22 × 143 × 800

22 × 143 × 1200

22 × 98 × 1200

22 × 98 × 1000

22 × 143 × 1000

22 × 78 × 1000

22 × 98 × 800

CP:

17 × 78 × 1200/1000/800

17 × 98 × 1200/1000/800

----------------------------------------------

1st and 2nd sorts are manufactured in following sizes (dimensions in millimeters):

22 × 143 × 1200

22 × 98 × 1200

-----------------------------------------------

78 × 78 × 1200/2400

78 × 98 × 1200/2400

78 × 143 × 1200/2400

MQO 100 m3

For more info about us and our products please contact us

- Pine / Spruce Pallet Elements

We offers timber and semifinished goods used for production of different types of wooden pallets.

The blanks of EURO pallets, CP pallets and non-standard pallets are made from conifer (fir and pine). The boards are fresh-cut and natural humidity.

Below are standard production dimensions of 1st and 2nd quality (dimensions in millimeters):

EURO:

22 × 143 × 800

22 × 143 × 1200

22 × 98 × 1200

22 × 98 × 1000

22 × 143 × 1000

22 × 78 × 1000

22 × 98 × 800

CP:

17 × 78 × 1200/1000/800

17 × 98 × 1200/1000/800

----------------------------------------------

1st and 2nd sorts are manufactured in following sizes (dimensions in millimeters):

22 × 143 × 1200

22 × 98 × 1200

-----------------------------------------------

78 × 78 × 1200/2400

78 × 98 × 1200/2400

78 × 143 × 1200/2400

MQO 100 m3

For more info about us and our products please contact us

We offers high quality pellets. We are based in Belgium, Poland and we sell all over Europe.

As I promised here are our prices including transportation:

PREMIUM Wood pellet 100% PINO A1 DINplus (65 bags * 24 pallets)

ROYAL A1 PINO DINplus (65 bags * 24pallet)

ROYAL COMFORT Premium quality 100% Pine A1 DINplus 10kg (very light pellets with 0.2% ash) (96 bags * 25pallets)

A2 Mix (pine, beech, oak) - (70 bags * 24 pallets)

RUF (beech, oak) 197 / t - 960 x 24 pallets = 23.04 t

We offer our customers only the best! Without lightening, gluing, solvents, just wood, raw materials and nothing else.

Heating power of our pellets and 4.9-5.3kWh / kg instead of ash content 0.5% - 0.7%.

In the production of pellets only the high quality raw material supplied by the best and reliable suppliers should be used. All products have DINplus A1 while a2 has the SGS laboratory certificate.

The pellet is packaged in 15kg or BIG BAG bags.

Our main motto is the guarantee of quality, the guarantee of punctuality, the guarantee of continuity!

All products are available on our website:

As I promised here are our prices including transportation:

PREMIUM Wood pellet 100% PINO A1 DINplus (65 bags * 24 pallets)

ROYAL A1 PINO DINplus (65 bags * 24pallet)

ROYAL COMFORT Premium quality 100% Pine A1 DINplus 10kg (very light pellets with 0.2% ash) (96 bags * 25pallets)

A2 Mix (pine, beech, oak) - (70 bags * 24 pallets)

RUF (beech, oak) 197 / t - 960 x 24 pallets = 23.04 t

We offer our customers only the best! Without lightening, gluing, solvents, just wood, raw materials and nothing else.

Heating power of our pellets and 4.9-5.3kWh / kg instead of ash content 0.5% - 0.7%.

In the production of pellets only the high quality raw material supplied by the best and reliable suppliers should be used. All products have DINplus A1 while a2 has the SGS laboratory certificate.

The pellet is packaged in 15kg or BIG BAG bags.

Our main motto is the guarantee of quality, the guarantee of punctuality, the guarantee of continuity!

All products are available on our website:

Dear Sirs,

We want EXPORTERS of SOFT ROUGH SAWN & KLIN DRY LUMBER WOOD A / B grade.

BLACK PINE / RADIATA PINE / SYP PINE / TADEA PINE.

We are already importing & need more suppliers . PRICE & QUALITY IS VERY IMPORTANT.

We manufacture PALLETS / INDUSTRIAL PACKING BOXES ETC. in INDIA.

PLEASE RPEPLY IN FULL DETAIL, EXACT NAME OF LUMBER, QUANITY in 40 Container, as well your company address, VAT N & REGISTRAZION N etc.. Only if interested on long term business.

OUR LUMBER SIZES AS FOLLOW REQUIRED:-

3200mm*95mm*95mm

2743mm*95 mm*95mm

2591mm*95mm*95mm

2440mm*95mm*95mm

2286mm*95mm*95mm

We require moor containers of 40 each month. BUT FIRST 1 (ONE) container will be trail order.

OUR PAYMENTS TERMS:- (NO ADVANCE PAYMENT) ONLY AGAINST IRRECOVERABLE & CONFIRMED LETTER OF CREDIT. Documents as below MUST BE GIVEN & to be sent through BANK to BANK.

PRICE should INCLUD OCEAN FREGIATE AS WELL INTRENAL TRASPORTATION TILL ICD KANPUR INPNK6 (INDIA). Measurement in METRIC CUBE & Correspondence only in ENGLISH. THANKS.

DOCUMENTS REQUIRED FROM THE SUPPLIER :-

A) 4 Copy of Commercial INVOICE in ORIGINAL.

B) 4 Copy of PACKING LIST in ORIGINAL.

C) CERTIFICATE OF ORIGIN ( GSP ) in ORIGINAL.

D) 3 ORIGINAL copy of Shipping Bill.

E) 1 ORIGINAL copy of PLANT QUARANTINE / PHYTOSANITARY CERTIFICATE. THIS CERTIFICATE IS ISSUSED BY THE GOVERNMENT DEPARTMENT FROM THE COUNTRY OF ORIGIN.

F) VGM CERTIFICATE ( Container Weighing and VGM DECLARATION as per SOLAS ).

We want EXPORTERS of SOFT ROUGH SAWN & KLIN DRY LUMBER WOOD A / B grade.

BLACK PINE / RADIATA PINE / SYP PINE / TADEA PINE.

We are already importing & need more suppliers . PRICE & QUALITY IS VERY IMPORTANT.

We manufacture PALLETS / INDUSTRIAL PACKING BOXES ETC. in INDIA.

PLEASE RPEPLY IN FULL DETAIL, EXACT NAME OF LUMBER, QUANITY in 40 Container, as well your company address, VAT N & REGISTRAZION N etc.. Only if interested on long term business.

OUR LUMBER SIZES AS FOLLOW REQUIRED:-

3200mm*95mm*95mm

2743mm*95 mm*95mm

2591mm*95mm*95mm

2440mm*95mm*95mm

2286mm*95mm*95mm

We require moor containers of 40 each month. BUT FIRST 1 (ONE) container will be trail order.

OUR PAYMENTS TERMS:- (NO ADVANCE PAYMENT) ONLY AGAINST IRRECOVERABLE & CONFIRMED LETTER OF CREDIT. Documents as below MUST BE GIVEN & to be sent through BANK to BANK.

PRICE should INCLUD OCEAN FREGIATE AS WELL INTRENAL TRASPORTATION TILL ICD KANPUR INPNK6 (INDIA). Measurement in METRIC CUBE & Correspondence only in ENGLISH. THANKS.

DOCUMENTS REQUIRED FROM THE SUPPLIER :-

A) 4 Copy of Commercial INVOICE in ORIGINAL.

B) 4 Copy of PACKING LIST in ORIGINAL.

C) CERTIFICATE OF ORIGIN ( GSP ) in ORIGINAL.

D) 3 ORIGINAL copy of Shipping Bill.

E) 1 ORIGINAL copy of PLANT QUARANTINE / PHYTOSANITARY CERTIFICATE. THIS CERTIFICATE IS ISSUSED BY THE GOVERNMENT DEPARTMENT FROM THE COUNTRY OF ORIGIN.

F) VGM CERTIFICATE ( Container Weighing and VGM DECLARATION as per SOLAS ).

We produce any type of furniture from pallets, mdf, solid wood, with good quality - -AT PRODUCER PRICES.

- kitchens

- full bedrooms

- Dressage (sliding door cabinets)

- Living room furniture

- Bathroom furniture

- garden furniture (pergolas, towers, wooden houses, etc.)

- solid wood

- solid wood balls

Prices vary depending on the dimensions, colors and accessories used (drawers, hinges, opening systems, handles, materials: Pal melamine, MDF, wood essence etc.).

Design, measurements, assembly, transport

Experience - 25 years in the field.

- kitchens

- full bedrooms

- Dressage (sliding door cabinets)

- Living room furniture

- Bathroom furniture

- garden furniture (pergolas, towers, wooden houses, etc.)

- solid wood

- solid wood balls

Prices vary depending on the dimensions, colors and accessories used (drawers, hinges, opening systems, handles, materials: Pal melamine, MDF, wood essence etc.).

Design, measurements, assembly, transport

Experience - 25 years in the field.

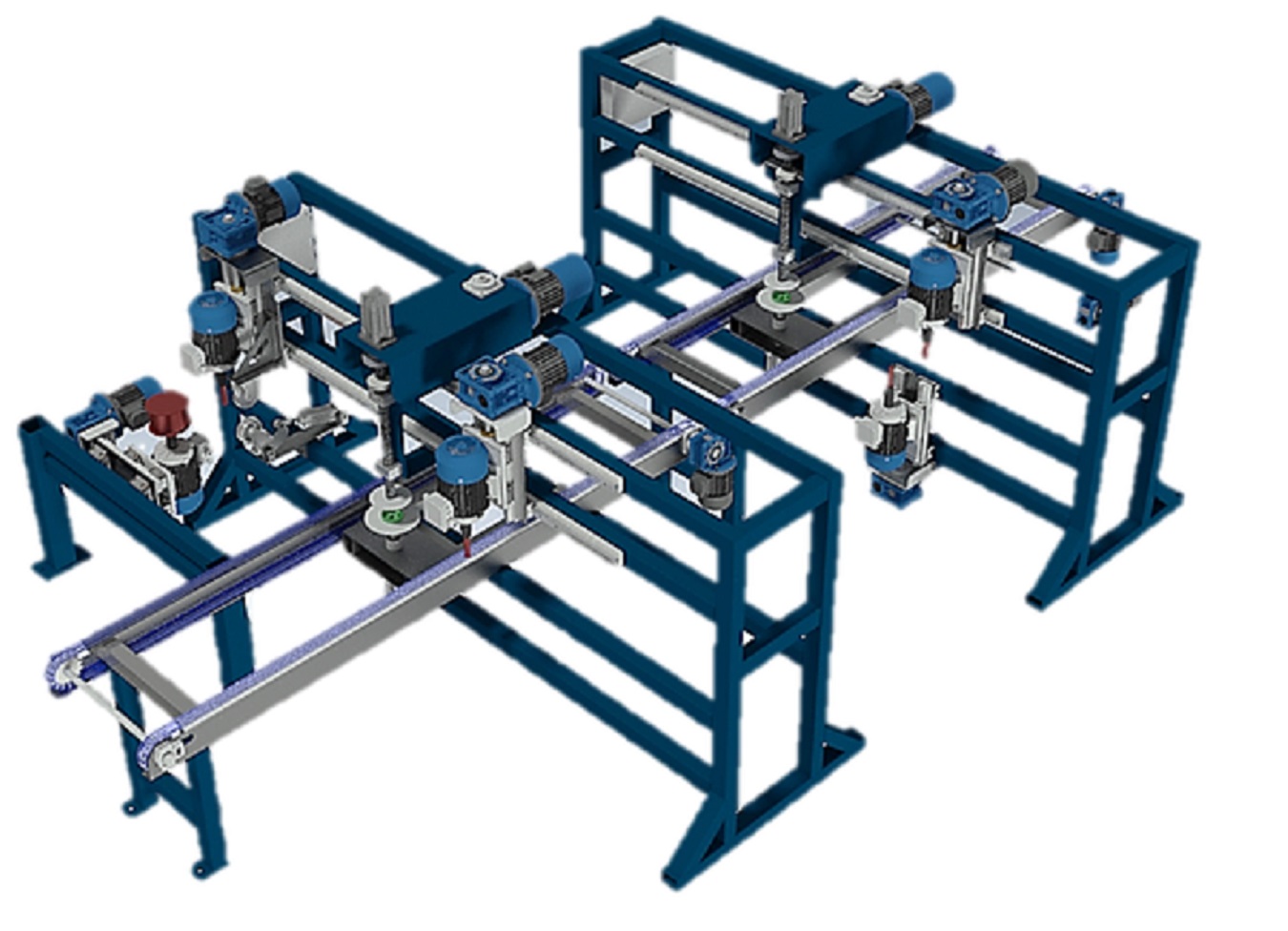

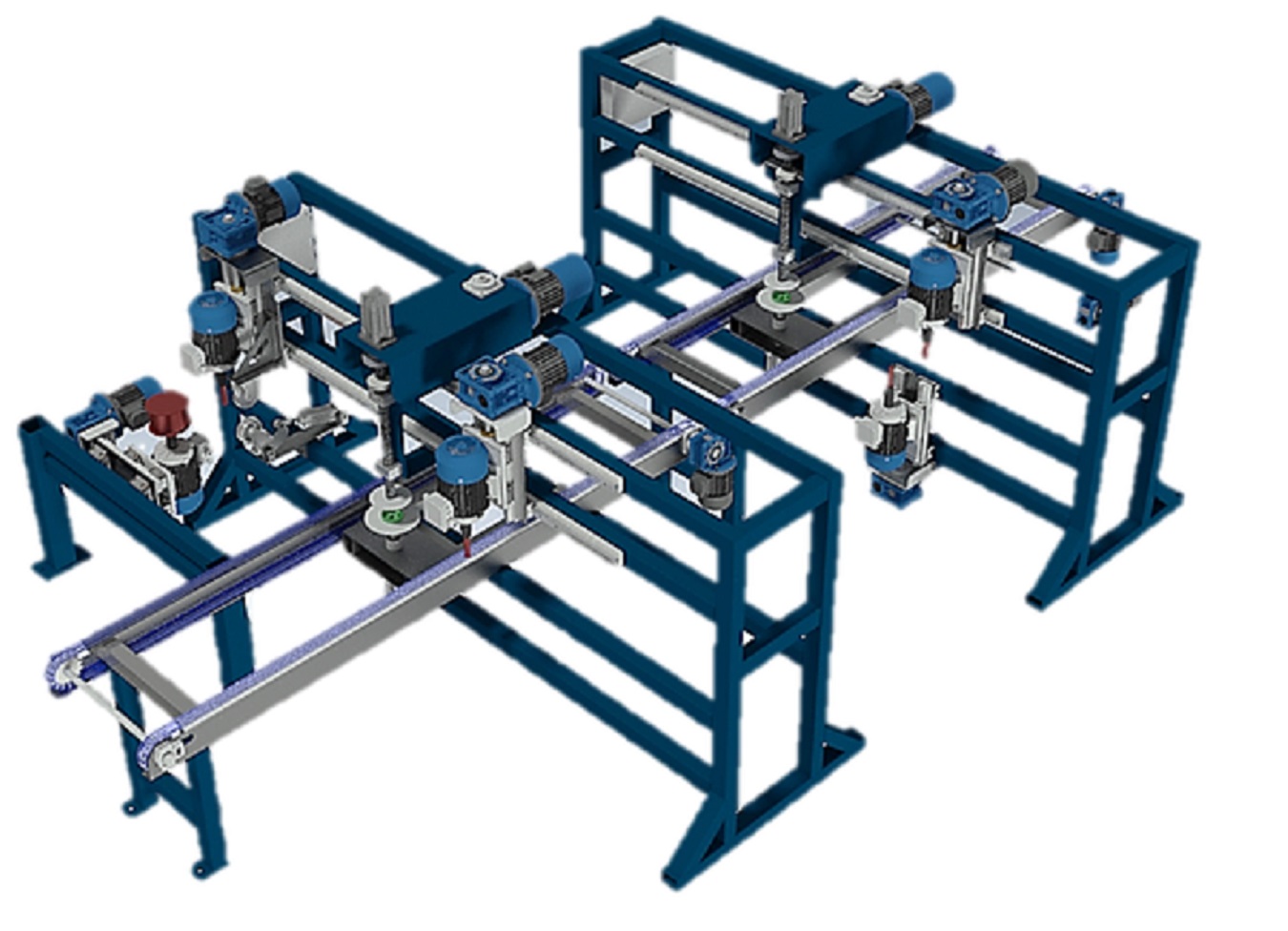

COMPACT LINE FOR THE MANUFACTURE OF FLANGES

Includes simple workbench for loading and fixing materials. 5-gun nailed machine for automatic and fast nailing

This offer is complete with all the terminal modules for finishing the flanges

Cutting-Extraction-Drilling-Planing-Storage Stations from 800 to 3000 mm diameter

All tools included. The line requires an operator and a capacity of up to 400 units in 8 hours

There is also a 6-meter long conveyor belt with 2 main stations and 1 stationary finishing station

The process is automatic, adjustments are manuals with a quick setup system

1. WORKBENCH OF PREFIXING MATERIAL

BANK LOADING MATERIALS FOR A SINGLE OPERATOR.

2. AUTOMATIC STATION FOR NAILING UP TO 6 PNEUMATIC GUNS

Description

The operator loads the nailed products in the correct positions to start the automatic cycle

Clean and bend burning nails C72.

Automatic extraction of assembled flanges.

Motorized base for flange rotation with control sensor

3. CIRCULAR EXTERNAL CUTTING MACHINE INTERNAL FLANGE CUTTING

AUTOMATIC CONNECTION WITH WIRE FIXED MACHINE

Description

Motorized base for rotating assembled flanges

# 3 Peneumatic locking systems

# 1 Automatic Milling Group for External Cutting of Flanges from 800 to 3000 mm in diameter

# 1 Automatic milling group for medium flange from 350 to 2000 mm

Manual adjustments for different diameters on high-quality linear INA guides.

4. PLANING MACHINE FOR FLANGES / SIMPLE PLANING MACHINE

Description

# 1 Automatic milling group for finishing flange edges

Sensor for the correct position of the flange

Automated tools managed by Omron PLC

5. AUTOMATIC MULTI-HOLE DRILLING MACHINE

Description

Motorized base for rotating assembled flanges

# 2 Pneumatic Locking System:

# 1 drill bit for drilling the connecting rods on the upper cable

# 1 burglary

Automatically pulling into the conveyor

Automated tools managed by Omron PLC

6. STORING THE FLANGES

CONNECTED TO THE LAST STATION. AUTOMATIC STORING MACHINE FOR FLANGES

Description

Conveyor belt with motorized chain

Opening / Closing adjustments by the operator.

# 2 Pneumatic cylinders to lock the pallet in the correct position.

Sensor for automatic lift action

Pneumatic system to move side supports

Maximum height 3000mm

Weight Up to 2000 kg

Lifting by High Performance Hydraulic System

Air pressure 6 bar

Pressure Hydraulic System 110 bar

Automatic forklift

7. Stacking 6 M

Description

Motorized Conveyor Belt

Stacking up to 2 stacks of flanges

Weight Max. 5000 kg

Automation management with OMRON PLCs and touch screen interface. The company performs and certifies in accordance with EC regulations. Release the verbal electrical test. Omron Independent Safety Unit according to EC regulations.

Security Sensor: Off, Perimeter Networks in Automated Area, # 1 Access Control Door Included in Offer

This system includes all security controls. Instruments also include the electrical system that was made in accordance with current legislation.

Warranty: 12 months from date of installation.

For the purposes of Legislative Decree no. 206/05, the warranty applies to non-compliant components, provided that the product has been used in accordance with its intended purpose. In the event of a replacement of the guarantee, Innuce Srl will take over the defective material as a result of the actual verification of defects claimed by the customer, without any cost to the Client; And / or if intervention is required, they undertake not to exceed 7 working days. Including non-compliance with the terms of sale and / or payment described in the contract, Innuce Srl may provide for the withdrawal and / or prohibition of the putting into service of the machines and / or parts thereof. The warranty will be invalidated for improper use of the machine if its parts have not been used and / or handled in accordance with the explicit instructions in the "User Manual and Maintenance" issued by the manufacturer at the time of delivery, which have been verified. In addition, any form of warranty is void if the car or its parts have been subjected to interventions by unskilled external technicians and / or not designated by the construction firm.

Includes simple workbench for loading and fixing materials. 5-gun nailed machine for automatic and fast nailing

This offer is complete with all the terminal modules for finishing the flanges

Cutting-Extraction-Drilling-Planing-Storage Stations from 800 to 3000 mm diameter

All tools included. The line requires an operator and a capacity of up to 400 units in 8 hours

There is also a 6-meter long conveyor belt with 2 main stations and 1 stationary finishing station

The process is automatic, adjustments are manuals with a quick setup system

1. WORKBENCH OF PREFIXING MATERIAL

BANK LOADING MATERIALS FOR A SINGLE OPERATOR.

2. AUTOMATIC STATION FOR NAILING UP TO 6 PNEUMATIC GUNS

Description

The operator loads the nailed products in the correct positions to start the automatic cycle

Clean and bend burning nails C72.

Automatic extraction of assembled flanges.

Motorized base for flange rotation with control sensor

3. CIRCULAR EXTERNAL CUTTING MACHINE INTERNAL FLANGE CUTTING

AUTOMATIC CONNECTION WITH WIRE FIXED MACHINE

Description

Motorized base for rotating assembled flanges

# 3 Peneumatic locking systems

# 1 Automatic Milling Group for External Cutting of Flanges from 800 to 3000 mm in diameter

# 1 Automatic milling group for medium flange from 350 to 2000 mm

Manual adjustments for different diameters on high-quality linear INA guides.

4. PLANING MACHINE FOR FLANGES / SIMPLE PLANING MACHINE

Description

# 1 Automatic milling group for finishing flange edges

Sensor for the correct position of the flange

Automated tools managed by Omron PLC

5. AUTOMATIC MULTI-HOLE DRILLING MACHINE

Description

Motorized base for rotating assembled flanges

# 2 Pneumatic Locking System:

# 1 drill bit for drilling the connecting rods on the upper cable

# 1 burglary

Automatically pulling into the conveyor

Automated tools managed by Omron PLC

6. STORING THE FLANGES

CONNECTED TO THE LAST STATION. AUTOMATIC STORING MACHINE FOR FLANGES

Description

Conveyor belt with motorized chain

Opening / Closing adjustments by the operator.

# 2 Pneumatic cylinders to lock the pallet in the correct position.

Sensor for automatic lift action

Pneumatic system to move side supports

Maximum height 3000mm

Weight Up to 2000 kg

Lifting by High Performance Hydraulic System

Air pressure 6 bar

Pressure Hydraulic System 110 bar

Automatic forklift

7. Stacking 6 M

Description

Motorized Conveyor Belt

Stacking up to 2 stacks of flanges

Weight Max. 5000 kg

Automation management with OMRON PLCs and touch screen interface. The company performs and certifies in accordance with EC regulations. Release the verbal electrical test. Omron Independent Safety Unit according to EC regulations.

Security Sensor: Off, Perimeter Networks in Automated Area, # 1 Access Control Door Included in Offer

This system includes all security controls. Instruments also include the electrical system that was made in accordance with current legislation.

Warranty: 12 months from date of installation.

For the purposes of Legislative Decree no. 206/05, the warranty applies to non-compliant components, provided that the product has been used in accordance with its intended purpose. In the event of a replacement of the guarantee, Innuce Srl will take over the defective material as a result of the actual verification of defects claimed by the customer, without any cost to the Client; And / or if intervention is required, they undertake not to exceed 7 working days. Including non-compliance with the terms of sale and / or payment described in the contract, Innuce Srl may provide for the withdrawal and / or prohibition of the putting into service of the machines and / or parts thereof. The warranty will be invalidated for improper use of the machine if its parts have not been used and / or handled in accordance with the explicit instructions in the "User Manual and Maintenance" issued by the manufacturer at the time of delivery, which have been verified. In addition, any form of warranty is void if the car or its parts have been subjected to interventions by unskilled external technicians and / or not designated by the construction firm.

Hello

We are constantly buying large quantities of europallets New and used

please offer everything

we pay daily price!

We are constantly buying large quantities of europallets New and used

please offer everything

we pay daily price!

We are authorized as the ultimate recycler R3 for wood packaging, and can also offer recycling services to meet the mandatory recycling targets set by the Environment through our company.

If you have a person who is responsible for environmental issues, or have outsourced this service please contact us.

We also offer europallets

- Use only once

- 1-27ron quality

- quality2-24ron

Pallets:

- euro pallets used 12 ron

- New pallets 1200x800,1200x1000, 1400x1000, 800x800 etc. to order according to your requirements.

For any other information please contact us.

If you have a person who is responsible for environmental issues, or have outsourced this service please contact us.

We also offer europallets

- Use only once

- 1-27ron quality

- quality2-24ron

Pallets:

- euro pallets used 12 ron

- New pallets 1200x800,1200x1000, 1400x1000, 800x800 etc. to order according to your requirements.

For any other information please contact us.

We are selling pallets and europallets new and second hand.

Our pallets are with full ISPM15 standard.

Best regards.

Our pallets are with full ISPM15 standard.

Best regards.

Hello colleagues !!

We buy large quantities Euro pallets New And Used

Also we buy lots of pallet elements

Maas

1200x100x22

1200x145x22

800x145x22

1200x75x17

800x75x17

600x75x17

We thank you for your fast offer.

We buy large quantities Euro pallets New And Used

Also we buy lots of pallet elements

Maas

1200x100x22

1200x145x22

800x145x22

1200x75x17

800x75x17

600x75x17

We thank you for your fast offer.

Hello

We Buy Big Quantities Euro Pallets New And Used

Please, give us an offer

Bekir U.

We Buy Big Quantities Euro Pallets New And Used

Please, give us an offer

Bekir U.

Hello

We buy large quantities of europallets New and used

We are buying large quantities of spruce and fir boards.

Fell free to contact us for more info about our demand

We buy large quantities of europallets New and used

We are buying large quantities of spruce and fir boards.

Fell free to contact us for more info about our demand